Want to extend the run time of your kayak electronics for longer fishing trips or tournaments? This article focuses on How To Connect 12V Batteries in Parallel. This can be easily acquired with the addition of a second SLA or LFP battery (LiFePO4) wired parallel. The second battery will need to be the same voltage as the first or they will work against each other which may result in heat issues or decreased run time. Also if you are using a SLA you must use the same type of battery in parallel due to the voltage issue.

You can create a parallel connection between 2 batteries with a few materials simply right at home.

Materials needed:

- (4) Female Spade Crimp On Connectors

- (2) 18″ length – 14 AWG Copper stranded wire w/ insulation Red & Black

- (2) Butt Connectors (optional)

- Fuse Block or Inline Fuse

- Blade Fuses

Tools:

- Wire strippers/crimps

- Heat Gun

Fabricating a Parallel Wire Harness:

Most small 12v batteries have male spade connectors on the top as battery terminals. Although some have other connectors its best to match them so you may disconnect the battery from the harness. Since the battery harness will be used in a wet marine environment its best to use marine grade heat shrink connectors.

Most small 12v batteries have male spade connectors on the top as battery terminals. Although some have other connectors its best to match them so you may disconnect the battery from the harness. Since the battery harness will be used in a wet marine environment its best to use marine grade heat shrink connectors.

The parallel harness will simply connect two batteries together on the same polarity. Positive to Positive and Negative to Negative. Seen in the diagram on the left, you will to wire in an inline fuse or fuse block on the positive side. Then adding a latching switch adds safety while plugging and unplugging devices around water.

If using an inline fuse the switch can be spliced in after. If using a fuse block a switch can be added before the block as a master switch. Also you may want a switch to control power to every accessory. In that case switch all positive leads from the fuse block. This comes in handy when running say lighting and a fish finder. Separate switches will operate each electrical device.

My Parallel Battery Project includes (2) 12V 12 aH LFP (LiFePO4) batteries. When completed total output will be 12V 24aH. This will extend the run time of the battery but will still power the same electronics.

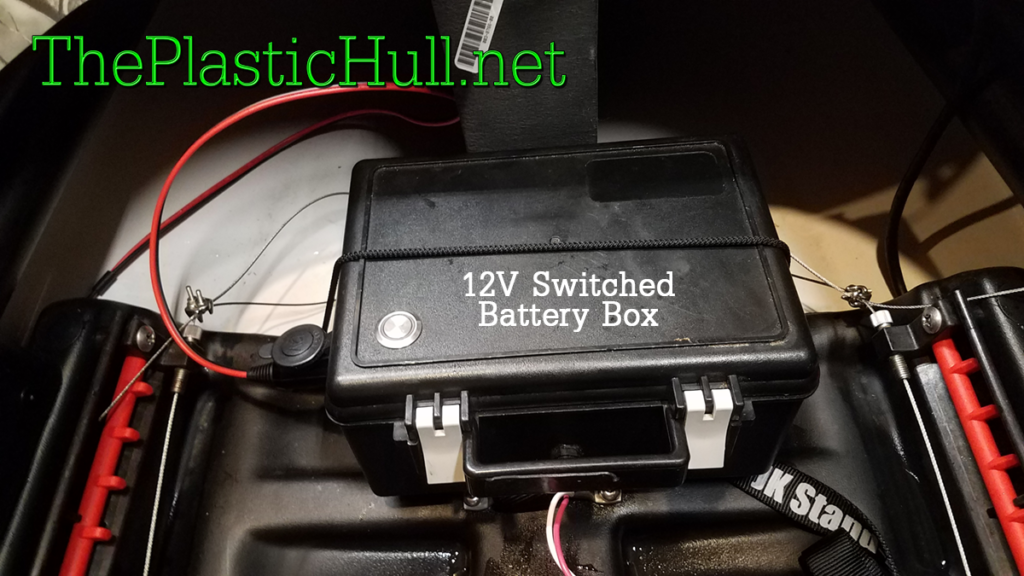

For building the battery box check out my post: Portable Water Resistant Enclosure & Switching