YakAttack LeverLoc install on Jackson Kayak Kraken (Permanent Install)

The Jackson Kayak Kraken being 15′-6″ long requires the use of pad eyes to guide the long anchor trolley. YakAttack has created a kit along with a locking feature so there is no need for clam cleats anymore. Low profile and a top of the line anchor trolley rigging solution.

The YakAttack Leverloc install on Jackson Kayak Kraken is pretty simple given the amount of access to the inside of the hull. In this article I will cover the YakAttack Leverlock HD kit & system. The kit includes additional backing plates to make the pulley anchor points more rigid.

In the kit you will find the following:

YakAttack LeverLoc HD Kit

Anchor Trolley Line

Anchor Trolley Line- (4) Pad Hooks

- (2) Harken Pulleys

- LeverLoc and Housing

- Trolley Ring

- (3) backing plates with rigging bullet capability

- Mounting Hardware

Tools Needed:

- Drill

- Screwdriver

- Lighter

- Center Punch

First check that the kit contains all parts you will need.

The included instructions are well written in a step by step fashion to guide you through the installation that best fits the application.

In this install we will be drilling only 2 holes at the pulley locations as with the Jackson Kayak Kraken there is ample inner hull access to these areas. On the (2) three hole backer blocks look for the word pulley. these are the 2 holes we will be fastening to.

The LeverLoc may be installed on either side of your kayak and is purely your discretion. Typically fishing with conventional rods and reels my preference is to install the anchor trolley on the left side of my kayak. Due to being right handed I tend to fish from the left side of the kayak. This allows me to control my fishing rod better and land my fish easier. Also being right handed the control of the line and LeverLoc is overall easier.

1. Pulley Install:

Choose a location 12″ back from the bow above the waterline. Using a center punch mark the first hole and drill. Now mount the pulley using the black 1″ 10-32 bolt in the first hole drilled. Tighten into the backing plate but do not tighten completely. Now level the pulley and mark the second hole location in the center of the pulley mouthing point. Pivot the pulley and backing pate out of the way and drill the second hole. Fasten the second bolt to the backing plate and tighten. Repeat the same steps for the rear pulley.

2. LeverLoc & Clamp Base Install:

Now for the lever lock. The Kraken does not have a way to access the inner area of the kayak for this location. Select the location within reach from your seat but not where your paddle sweep will allow your hand or the paddle to hit. The screws provided will thread into the plastic without worries of them working out or leaking.

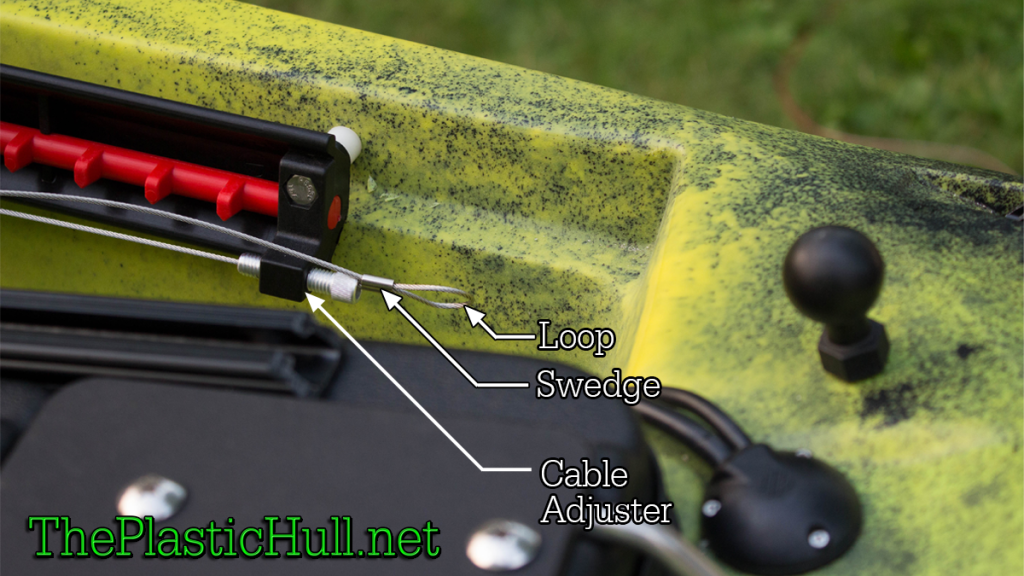

3. Trolley Line:

Tie an overhand knot in the end of the paracord after running it through one side of the ring. Now run the paracord through the bottom of the bow pulley then the top of the stern. Make sure you run it from the stern up through the pulley then through the Clamp Base then down through the front pulley. Tie off the ends to the trolley ring. Make sure there is no slack in the line.

4. Pad hook Install:

For locations where the paracord line rides up the gunnel you will install the pad hooks. The top line will run through and the bottom will clip in the bottom hook. Evenly spacing 2 at the stern to the center and 2 from the bow to the center seems to be the best placement.

5. Tie off

Tie the tag end of the trolley line to the ring using half hitches. Cut the remaining end but leave about 3 inches for future adjustment.

Disclaimer:

A short drive down to the boat ramp we dropped our kayaks in. The river is slightly brackish and is tidal water. It was a really low tide and everywhere I went my paddle bumped the bottom. The Kraken paddles really well. Turning was improved significantly with the addition of the Tru Course Rudder system! The kayak is truly a big water fast and stable boat.

A short drive down to the boat ramp we dropped our kayaks in. The river is slightly brackish and is tidal water. It was a really low tide and everywhere I went my paddle bumped the bottom. The Kraken paddles really well. Turning was improved significantly with the addition of the Tru Course Rudder system! The kayak is truly a big water fast and stable boat.